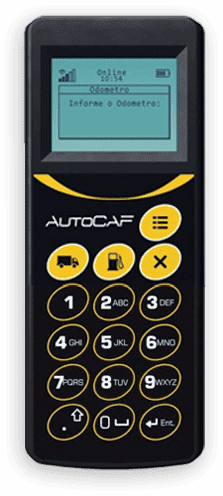

O software

A visualização dos mais importantes dados da frota, acompanhe o desempenho global ou individual dos veículos e operadores, além de obter um controle preciso sob o estoque.

Bloqueie veículos que apresentarem consumo inadequado

Obtenha relatórios gerenciais de forma fácil e rápida

Monitore o estoque e receba alertas de nível baixo

Acesse em nuvem, basta estar conectado à internet

- Custo acessível

- Fim de anotações em papel

- Relatórios personalizados

- Implantação rápida

- Permite integração com sistemas terceiros

- Compatível com bombas eletrônicas, mecânicas e caminhões comboio

Quem confia no nosso trabalho

Autocom - Tecnologia em Automação

- Rua Governador Pedro de Toledo, 2008 - Araçatuba/SP